In today’s fast-paced world, we rely heavily on machines and equipment to keep our industries running smoothly. But what happens when we overlook the signs of potential failures? 🤔 Unfortunately, the price we pay for ignoring condition monitoring can be steep.

Let’s go thru the scenario below.

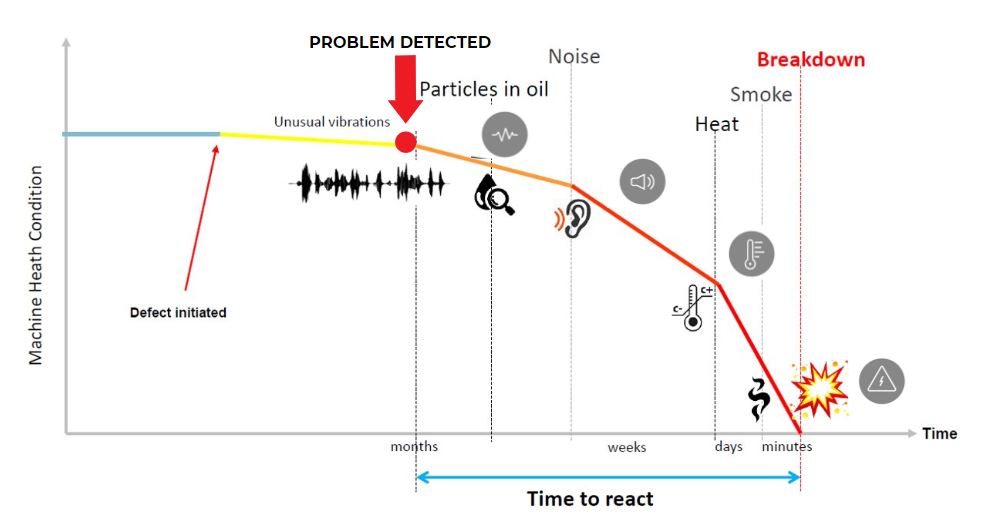

A pump’s condition monitoring failed to address unusual vibrations, leading to a cascade of escalating problems. The initial detection of these vibrations should have triggered immediate action, as they often indicate misalignment, imbalanced parts, or worn-out bearings. However, the lack of timely intervention allowed the root cause to persist and worsen over time, potentially causing additional complications.

As a result of the unaddressed vibrations, the pump started experiencing oil leakage after a few weeks. This leakage may have been caused by deteriorating seals or gaskets within the pump. Operating the pump with oil leakage further exacerbated the situation, compromising its lubrication and cooling systems. Inadequate lubrication can lead to increased friction, heat generation, and accelerated wear and tear of internal components.

The neglected issues eventually led to noticeable noises, a clear warning sign of mechanical stress such as the rubbing or scraping of components. These noises indicated further deterioration and the urgent need for attention.

Subsequently, the pump’s temperature significantly increased due to prolonged friction and inadequate cooling caused by the compromised lubrication system. The rise in temperature pointed to severe stress and inefficiencies within the pump, potentially causing thermal damage to critical components.

The observation of smoke emanating from the pump indicated a critical failure stage. The combination of high temperatures and potential oil leakage posed a risk of oil igniting or components overheating to the point of combustion. The visible smoke clearly indicated that immediate shutdown and attention were necessary to prevent further damage or safety hazards.

Ultimately, due to the prolonged neglect and failure to address the initial warning signs, the pump experienced a complete breakdown. The accumulation of issues, starting from unusual vibrations to oil leakage, noise generation, excessive temperature rise, and eventual breakdown, emphasizes the importance of timely condition monitoring and proactive maintenance.>>>>>

Remember, prevention is always better than cure!

This scenario underscores the significance of recognizing early warning signs and effectively implementing condition monitoring practices. Regular inspections, data analysis, and prompt intervention based on monitoring results are essential for identifying and resolving issues before they escalate. By adopting such practices, organizations can minimize downtime, reduce maintenance costs, and ensure the reliability and longevity of critical assets.

🛡️💙 Don’t ignore the warning signs. Embrace condition monitoring, and let’s safeguard our operations, our people, and our success. 💪✨