A key objective for industrial companies is meeting growing production demands with existing equipment and facilities while continuing to reduce costs to deliver the maximum return on assets (ROA). Organisations must find the optimum balance between asset availability and asset utilization. Condition Monitoring software is an intelligent solution that collects and analysis real-time diagnostics from all plant production assets to make better asset management decisions and optimize operations.

Real-Time Condition Monitoring improves situational awareness for all your team members by providing them with a single interface and repository for maintenance, control, and safety. Accelerate time to resolution with knowledge capture and information sharing to make better-informed decisions that drive improvement in operations.

Integration with Critical Plant Systems

Condition Monitoring software ties condition information together with required actions for critical plant systems and business solutions. In the plant environment, this includes integration with the Control/PLC/SCADA and Safety solutions, where access to key information is provided through the operator console.

Operator visualization is seamless. Data is presented through the operator interface, where key information such as asset performance trends, maintenance history, and operational specifications are presented to the operator directly on their screen.

Early Failure Detection

By understanding the condition of an asset, Condition Monitoring can help increase asset availability, reduce costs, and avoid unnecessary maintenance and downtime.

This supports continuous improvement through an integrated workflow management capability, and provides operations, engineering, and maintenance with easy access to current asset information for better decision making.

Easy Configuration

A simple configuration tool provides the linking mechanism between the Asset Registry and a wide range of plant information sources. It empowers the process engineer to link and configure the monitoring parameters for equipment and measurement points, define the analysis to be applied, and define the required actions/workflow resulting from the analysis.

On one screen, the configurator lists plant floor information points and the plant’s assets, as seen in the asset registry. It offers an intuitive drag-and-drop wizard-based environment, which facilitates the setup of simple or complex conditions across single or multiple assets and measurement points.

Data Analysis

Condition Monitoring analyseis data from multiple disparate assets, systems, and devices to help businesses understand their asset’s contribution to business operations throughout the entire asset lifecycle.

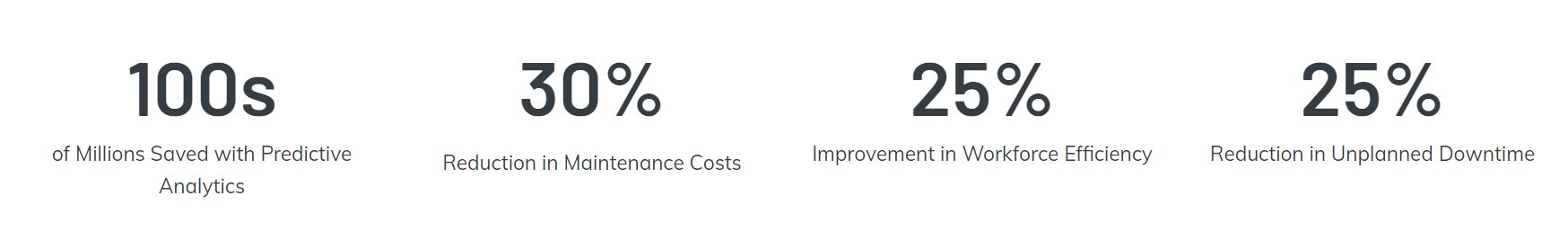

Source: AVEVA