Asset Management

Sky is Limitless with Asset Performance Management 4.0 (from existing content)

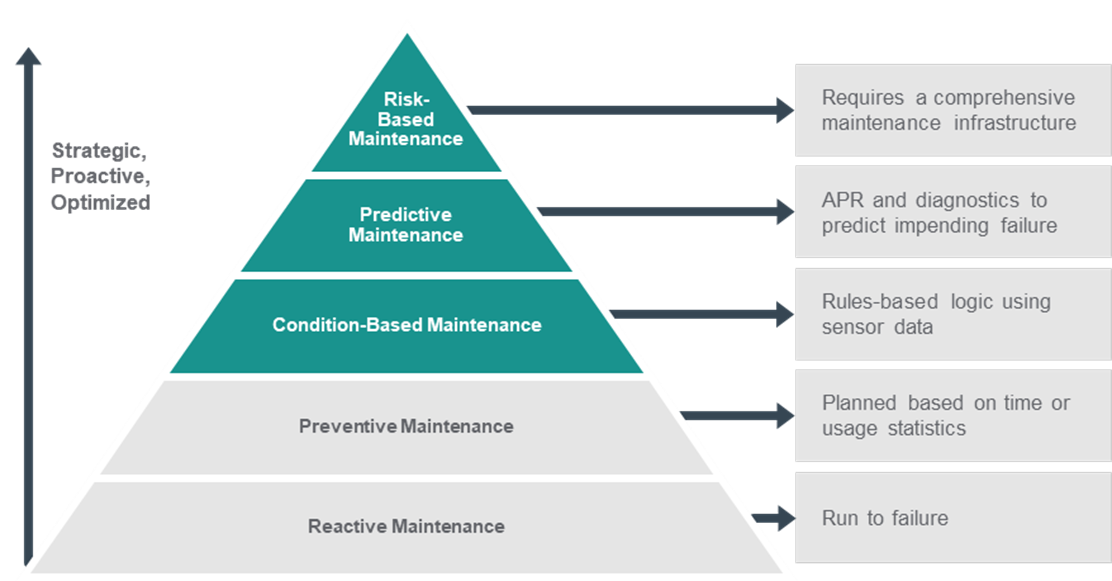

ASSET PERFORMANCE MANAGEMENT (APM) is a poorly understood and underutilized opportunity for asset-intensive industries. As we forge ahead through the age of Digital Transformation with Industry 4.0 or Smart Manufacturing, APM is at the frontline as a critical component for success. Let’s answer this; do your operations suffer from significant downtime due to equipment failure? Downtime will cause your organization to be less efficient, effective and productive.

With ASSET PERFORMANCE MANAGEMENT (APM) SOLUTIONS, YOU CAN NOW:

1. Maximize Return On Assets

2. Bridge the IT/OT Gap

3. Reduce Unscheduled Downtime

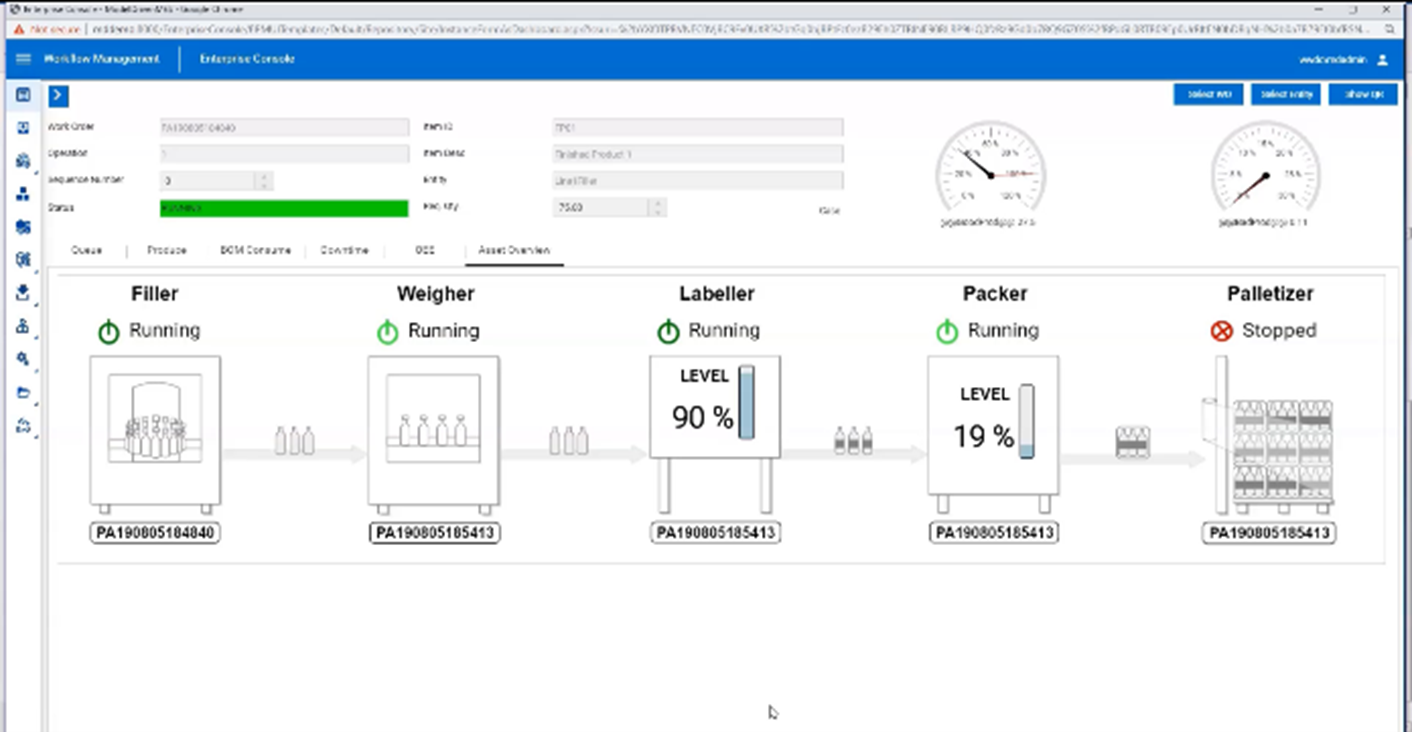

4. Optimize Asset Utilisation

5. Increase Operational Efficiency

Managing assets is not a cost center, but an Opportunity for Value Creation. Enter APM 4.0 – an evolutionary step for you to bring together the essential elements to succeed in the new age.

Computerized Maintenance Management System (CMMS)

- Enterprise Asset Management

- Maintenance Work Order Management

- Maintenance Request Portal

- Preventive Maintenance

- Mobile App

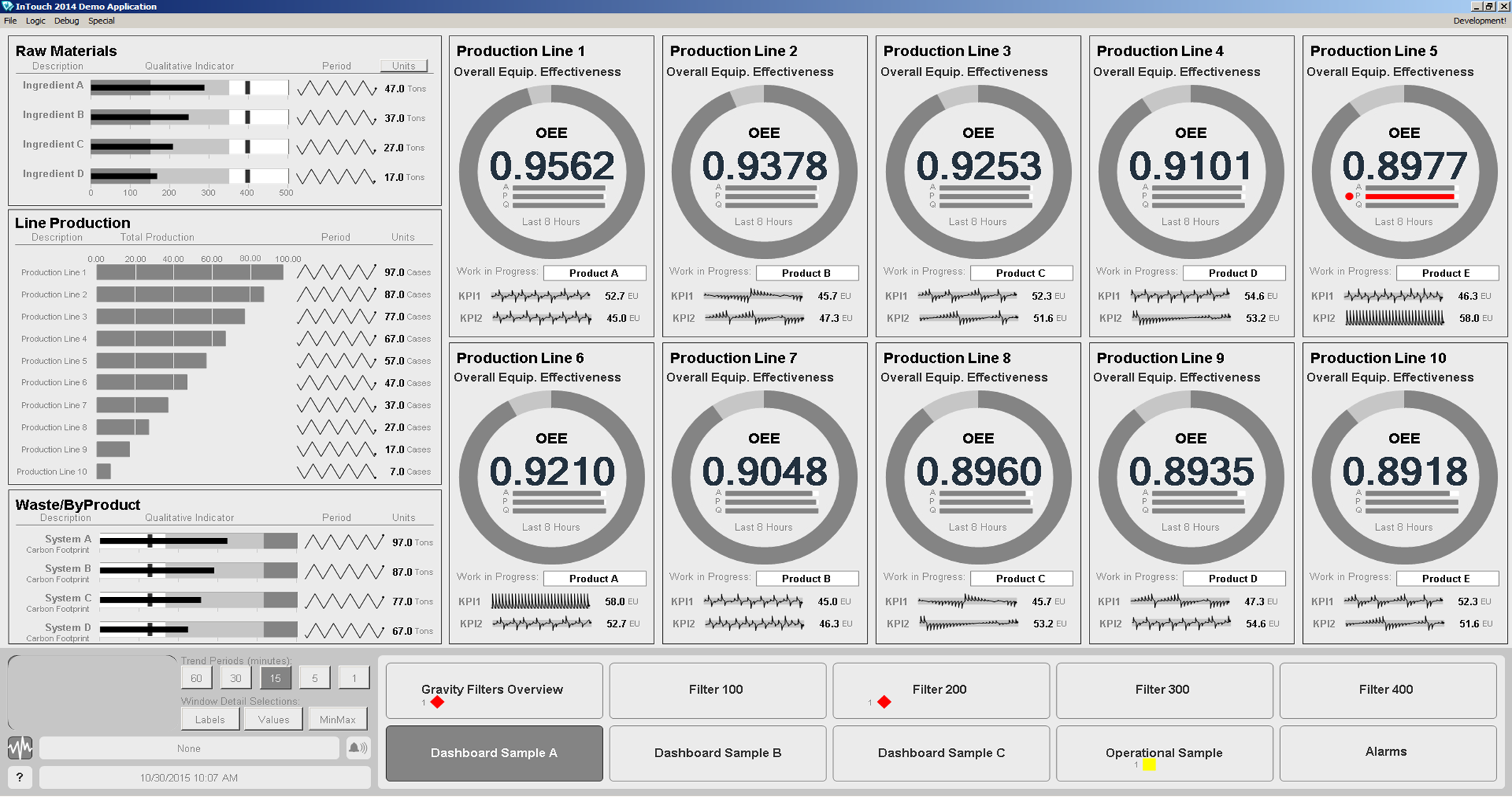

- Dashboard & Reporting

- Vendor Management