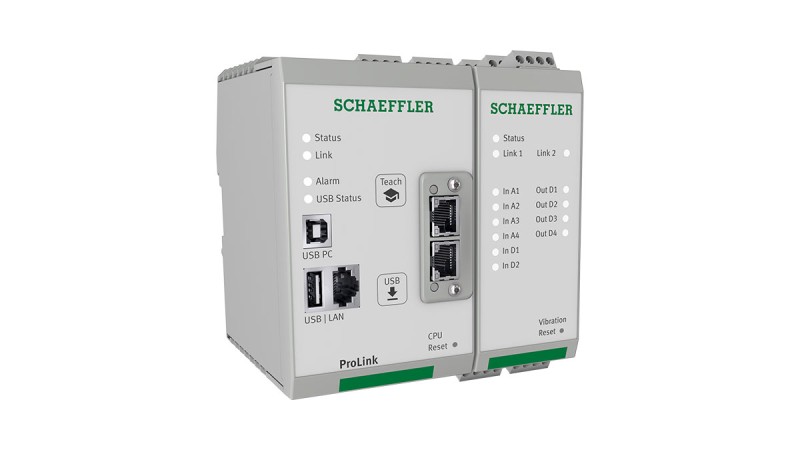

ProLink CMS – Versatile, Modular, and Easy to Interlink

Vibration measurement is used by the ProLink multi-channel condition monitoring system to monitor the condition of machinery and equipment.

The ProLink condition monitoring system has the following features:

- Templates for monitoring rolling bearings, motors, gearboxes, fans, and pumps that facilitate future configuration. All that is required is information regarding the machine geometry, such as the installed bearing type or the number of fan blades.

- Individual modifications to alert thresholds are possible in the learning mode to optimize monitoring.

- Customers will be able to use the ConditionAnalyzer via the integrated cloud interface as an option in the future.