INDUSTRY

Risks

- Without information on the parameter of Water Treatment Plant

- Unable to predict raw water

- Unable to determine filter performance

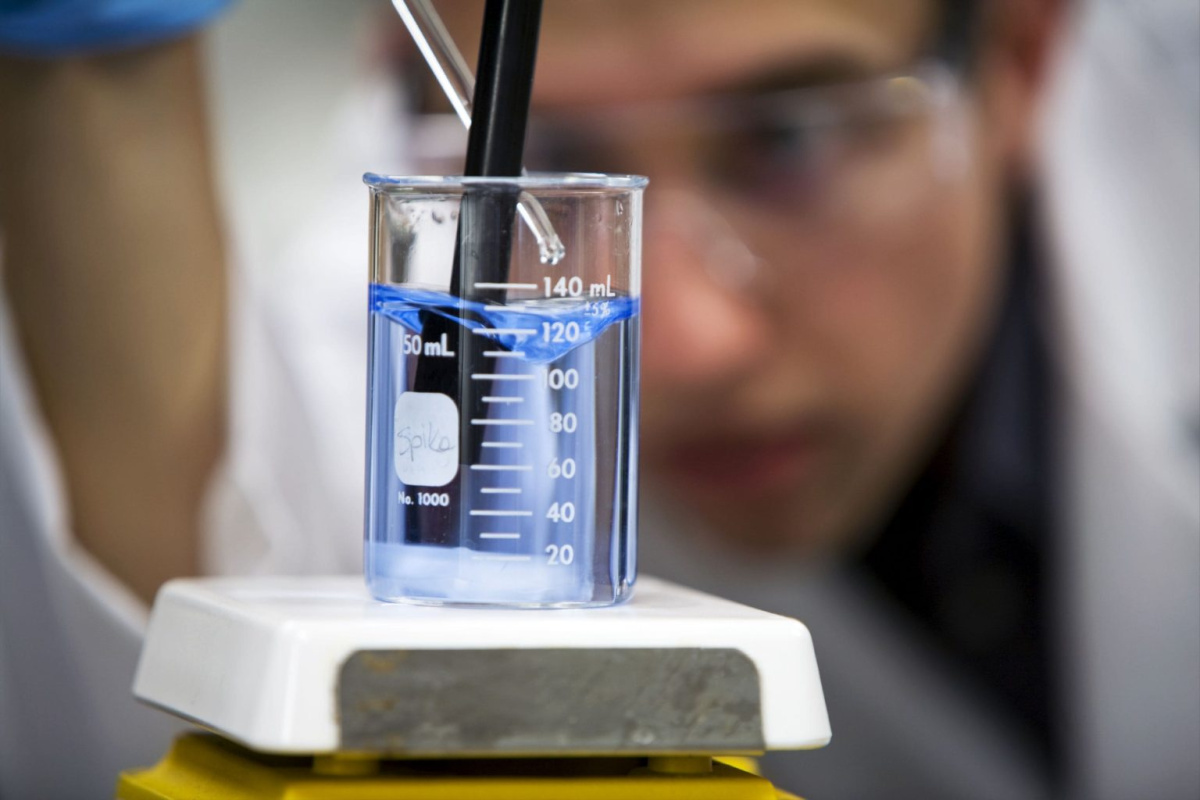

Our client is one of the biggest local water authorities in the central region, their daily operation of a water supply system is managed by internal staff with their experiences and expert judgment to adjust control elements. However, our customer found out that:

- Without information on the parameter of Water Treatment Plant

- Unable to predict raw water availability, suitability and quality

- Unable to determine filter performance and water loss

- Unable to predict and forecast the chemical usage and availability

- Unable to determine energy utilization and energy usage vs production output analyze

- Unable to determine pump efficiency utilization monitoring

- No operating condition monitoring for the pump

- All Maintenance work and record are still on paper

- Without overview & high level of visualization in Water Treatment Plant

Our team is tasked to provide a proactive and situation awareness system to monitor, control and analyze critical issues and concerns arising from the Water Treatment Plant.

Throughout the whole discussion of improvements, we proposed to set up treatment plant and equipped with intelligent communication that heightens situation awareness of the water department network. This was done by implementing a digital dashboard for energy consumption, raw water sustainability, clear water sustainability, chemical stock management, and asset management.

This has resulted that the team can now control the water treatment plant as an overview. They are now making better-informed business decisions with the new implementation of Smart Manufacturing:

- Issue and problem awareness alert.

- More effective on coordination and communication.

- Effective decision-making with more info and data.

- Maintenance and scenario planning is easier.

- All issue raises will be recorded in digital form.

- Dashboard for energy consumption, raw water sustainability, clear water sustainability, chemical stock management, and asset management.