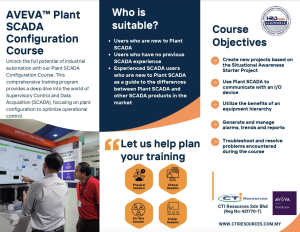

AVEVA™ Plant SCADA Configuration Course

Unlock the full potential of industrial automation with our Plant SCADA Configuration Course. This comprehensive training program provides a deep dive into the world of Supervisory Control and Data Acquisition (SCADA), focusing on plant configuration to optimize operational control.

Over the course, participants will engage in hands-on exercises, covering key aspects such as system setup, tag configuration, HMI design, and system integration. Gain practical insights into real-world applications, troubleshooting, and best practices to enhance your ability to configure and manage Plant SCADA systems effectively.

Whether you’re an entry-level professional or an experienced engineer, this course caters to all skill levels, offering a dynamic and immersive learning experience. Elevate your proficiency in Plant SCADA Configuration – Enroll now to acquire the skills essential for maximizing efficiency and control in industrial processes.

FREE One Day Technical Workshop (worth RM2888)

With Purchase of AVEVA Plant SCADA Configuration Training Course

Elevate your expertise with our exclusive 4-day AVEVA Plant SCADA Configuration Course, now offered complimentary with four additional free courses.

Dive deep into the intricacies of SCADA systems, from fundamental concepts to advanced configuration and integration. Gain hands-on experience with industry-leading AVEVA software, learn best practices in system security, alarm management, data analysis, and more.

Get Additional 4 Courses with, Free 1 Day Practical Hands-On Workshop:

- AVEVA Plant SCADA Redundancy

- How to connect PLC to AVEVA Plant SCADA

- Connecting SQL Database to AVEVA Plant SCADA

- Bonus Video: Integrate Telegram into AVEVA Plant SCADA

| Date | Days | Duration | Time (SGT) | Method | Class Type |

| 25 – 28 Nov 2024 | Mon – Thurs | 4 Days | 9:00AM – 5:00PM | Physical / Virtual Training | Public / Inhouse Training |

| 3 – 6 Feb 2025 | Mon – Thurs | 4 Days | 9:00AM – 5:00PM | Physical / Virtual Training | Public / Inhouse Training |

| 19 – 22 May 2025 | Mon – Thurs | 4 Days | 9:00AM – 5:00PM | Physical / Virtual Training | Public / Inhouse Training |

| 16 -19 Jun 2025 | Mon – Thurs | 4 Days | 9:00AM – 5:00PM | Physical / Virtual Training | Public / Inhouse Training |

| 11 – 14 Aug 2025 | Mon – Thurs | 4 Days | 9:00AM – 5:00PM | Physical / Virtual Training | Public / Inhouse Training |

| 13 – 16 Oct 2025 | Mon – Thurs | 4 Days | 9:00AM – 5:00PM | Physical / Virtual Training | Public / Inhouse Training |

By the completion of this training course, you should be able to:

- Create new projects based on the Situational Awareness Starter Project

- Use Plant SCADA to communicate with an I/O device

- Utilize the benefits of an equipment hierarchy

- Create graphics pages and manipulate graphics symbols

- Generate and manage alarms, trends and reports

- Troubleshoot and resolve problems encountered during the course

- Use the online Plant SCADA Help Topics and Knowledge Base effectively

Course Outline:

Module 1 – Introduction

Module 2 – Project Management

Module 3 – Architecture and Topology

Module 4 – I/O Communications

Module 5 – Equipment

Module 6 – Configuring Mixer Plant

Module 7 – Content Pages

Module 8 – Navigation

Module 9 – Graphic Elements and Animation

Module 10 – Operator Input

Module 11 – Genies

Module 12 – Popup Pages

Module 13 – Composite Genies

Module 14 – Faceplates

Module 15 – Alarm Configuration

Module 16 – Alarm Management

Module 17 – Cicode

Module 18 – Configuration Data Import and Export

Module 19 – Devices

Module 20 – Events

Module 21 – Trends

Module 22 – Reports

Module 23 –Advanced Graphics

Module 24 – Security

Appendix A – Industrial Graphics

Appendix B – Additional Exercises

The Plant SCADA Configuration training course is an integral part of the Citect

curriculum. This course is designed for:

- Users who are new to Plant SCADA

- Users who have no previous SCADA experience

- Experienced SCADA users who are new to Plant SCADA as a guide to the

differences between Plant SCADA and other SCADA products.

It is expected that trainees will:

- Be familiar with the concepts of PLCs

- Be familiar with the concepts of industrial automation

- Be familiar with Microsoft Windows.