AVEVA™ Operations Control

The industrial software subscriptions using hybrid cloud technologies to provide transparency and control for managing your operations.

Operations Management as a Pillar

AVEVA Operations Control helps industrial businesses to reconsider their HMI/SCADA strategy. You can use the knowledge and capabilities available to boost productivity, operational effectiveness, and profitability by removing architectural constraints and linking teams with full capability and released real-time data.

AVEVA Operations Control, as a user-centric industrial software subscription, gives you access to both on-premises and cloud applications, providing you the flexibility to choose the configuration, architecture, and deployment options that best fit your needs.

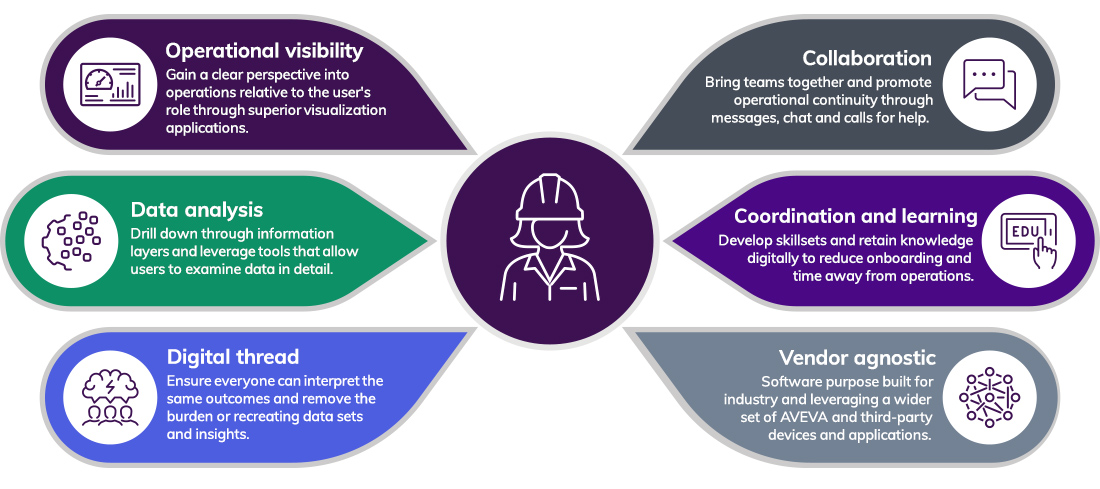

Aligning Teams Towards Operations Excellence

Operations Control – Quick Overview

- Subscription to user-centric software

- Flexibility in architecture, including hybrid-SaaS

- Access to extensive and limitless software capabilities

- Visualization of HMI/SCADA with mobility

- Historian of the Process

- Client reporting and analysis

- Dashboard analytics with AI insights

- Communication within the team and collaboration

- Management of knowledge and skills

- Execution of manufacturing

- Drivers of communication

- Tools for development

- Diagnostic and system health tools

- Technical support and software updates are included

Work procedures and knowledge should be scaled

Allow operators to be mobile with infinite visualization and use the cloud to boost cooperation and knowledge sharing to generate continuous improvement.

Improve results proactively

Enhance real-time and historical process data with machine learning and AI skills to identify and prevent any problems or breakdowns.

Improve operational awareness

By ensuring that everyone operates from the same digital thread, you may increase decision agility while also giving process assistance during execution.

Flexibility Allows for Operational Simplicity

In a hybrid cloud and on-premises setup, AVEVA Operations Control provides extensive capabilities such as visualization, mobility, data storage and analytics, collaboration, and development tools.

Operational Visibility

- Unlimited architectural flexibility

- Responsive web clients

- Engineered and self-service applications

- Templatization, styling, and standardization options

- Vector-based graphics libraries

- Portable graphics, with built-in editor

- Extensible functionality with apps and widgets

- Alarm management

- Collaborative on-premises and cloud development

- Security and authentication management

Digital Thread

- High performance database

- 2 million+ tags supported

- Tiered Historian architecture options

- Capture process values. Summary values, engineering units, alarms/events, acknowledgements, and annotations

- Secured store and forward for intermittent networks

- 13+ data retrieval modes

- Historical playback through visualization

- Seamless data integration and extensibility

Data Analysis

- Examine and replay data trends

- View trends and historical data within visualization

- Self-service dashboards available on-premises and in the cloud

- AI supported predictive insights and visual anomaly detection

- Easily assemble dynamic and custom reports for digital distribution

- Query and export data for further use in other applications like Microsoft Excel

- Replicate data into AVEVA PI System, AVEVA Data Hub

Connected Collaboration

- Post messages tagged to specific assets or areas, and people

- Apply filter criteria and search posts

- Attach videos and imagery to provide greater context to posts

- Receive notifications and updates on posts

- Raise issues and request help from colleagues and assigned experts

- Scan QR codes to link directly to asset content

- Store asset information like manufacturer, model, location, and equipment documentation

- Create digital forms and define submission processes

Coordinated Micro-learning

- Capture work instructions and troubleshooting resolutions as video and imagery

- Tag relevant content to specific equipment

- Structure training content with categories, assets, locations, and languages

- Setup training approval and revision workflows

- Customize skill types and attach required learning content

- Measure staff skill levels and promote upskilling

- Manage skill coverage and ensure staff resiliency

- View staff profile with activity, assignments, and skills information

Vendor Agnostic

- Utilize drivers for telemetry – DNP/IEC, IoT – MQTT/OPC UA, industrial standards – Modbus/SNMP, and proprietary protocols – Rockwell, Siemens, BACnet, GE, Beckhoff and more

- Take advantage of REST and other API types

- Export data in common formats

- Deploy software across various OS, cloud infrastructure, and architectural requirements

- Sync user management with authentication services

- Leverage AVEVA’s product partner network for joint hardware and software solutions