Asset Management

Vibration Sensor

AISSENS 100AW

Leading the Way in Industrial Condition Monitoring

The ASUS IoT AISSENS 100AW is a cutting-edge wireless vibration and temperature sensor featuring tri-axial 6 kHz sensitivity. It’s specifically engineered to detect early signs of gear, belt, and bearing faults, making it essential for proactive maintenance strategies. By enabling precise condition monitoring, it helps ensure continuous operation, prolong machinery life, and shift maintenance from routine schedules to data-driven decision-making—optimizing resources and reducing unexpected downtime.

Advanced Condition Monitoring Vibration Sensor

Reliable Monitoring Across Conditions: Key Specifications

Standard MQTT IoT Messaging: Agile Data Transmission for Flexibility & Speed

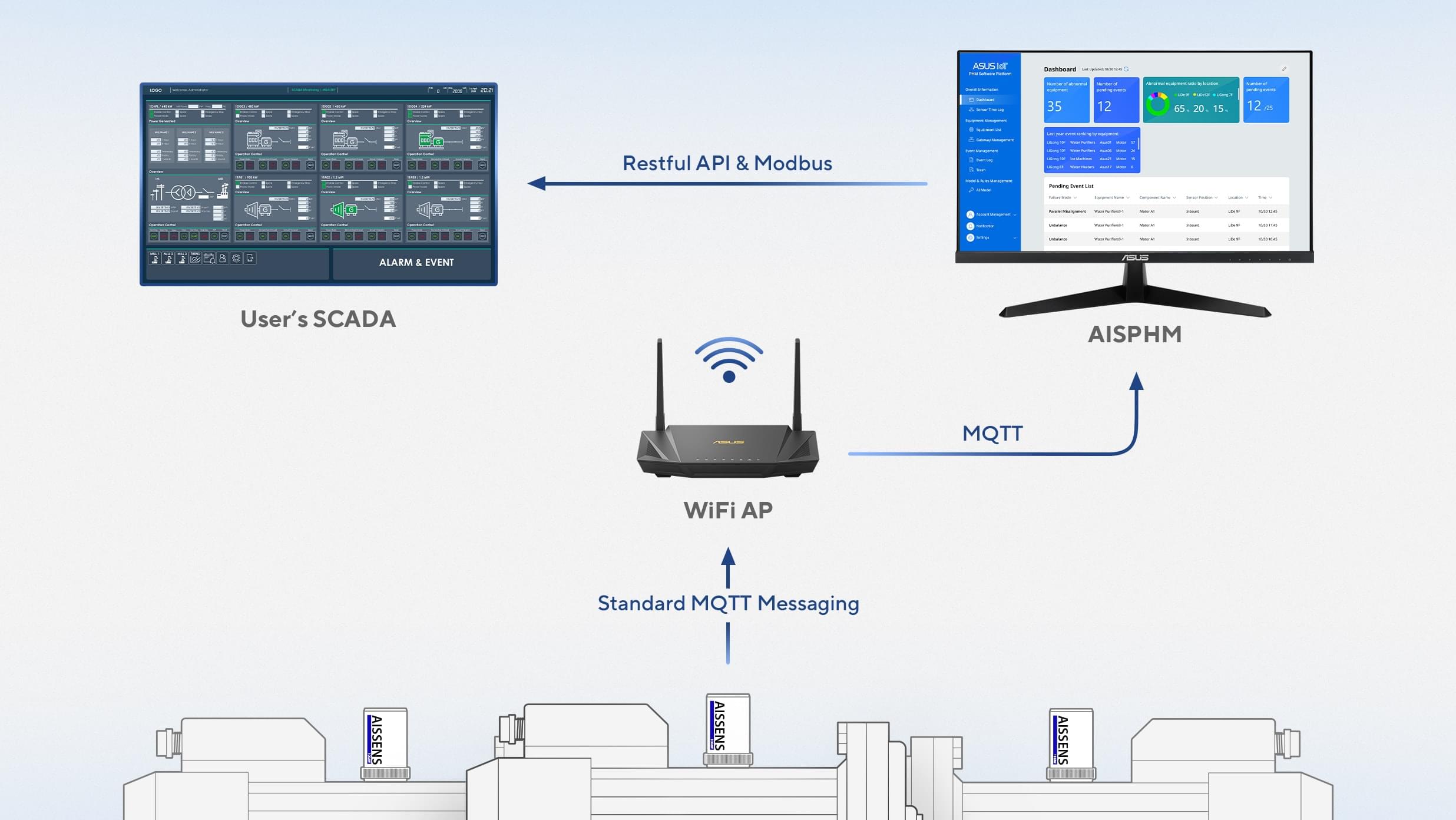

The AISSENS 100AW seamlessly integrates with SCADA systems using MQTT and Modbus protocols, enabling tailored monitoring solutions. It offers data options including RAW DATA, Feature DATA, OA, or FFT to address diverse diagnostic requirements. With support for OTA firmware updates, the sensor stays current with the latest features and security enhancements, ensuring consistent high performance.

AISPHM

Predicting Health, Preventing Problems

ASUS IoT AISPHM uses real-time AI and advanced vibration analysis to detect early faults in rotating equipment, ensuring reliable performance and reducing downtime. With flexible on-premise or cloud deployment, it delivers instant alerts and helps industries maintain continuous production while protecting equipment health.

Advanced vibration-analysis solution empowers predictive maintenance and equipment health management.

RESOURCES