PRODUCTION OPTIMIZATION

AVEVA™ Manufacturing Execution System

What is AVEVA™ Manufacturing Execution System?

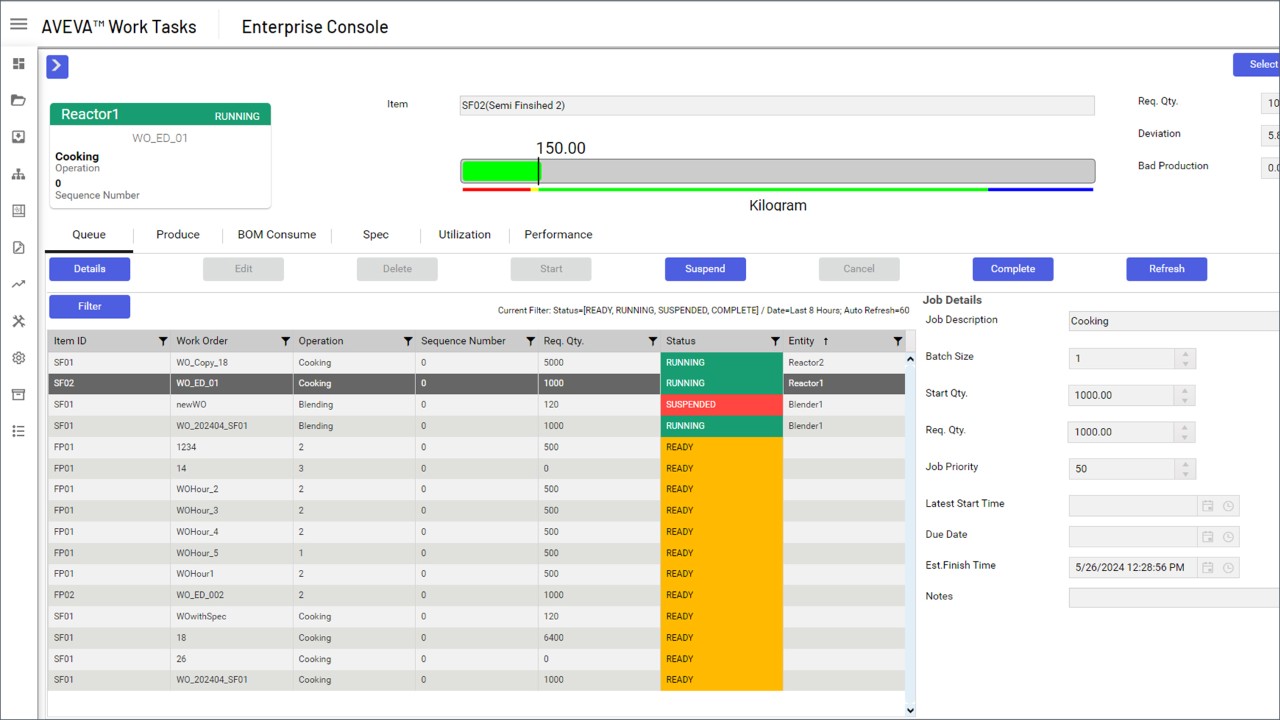

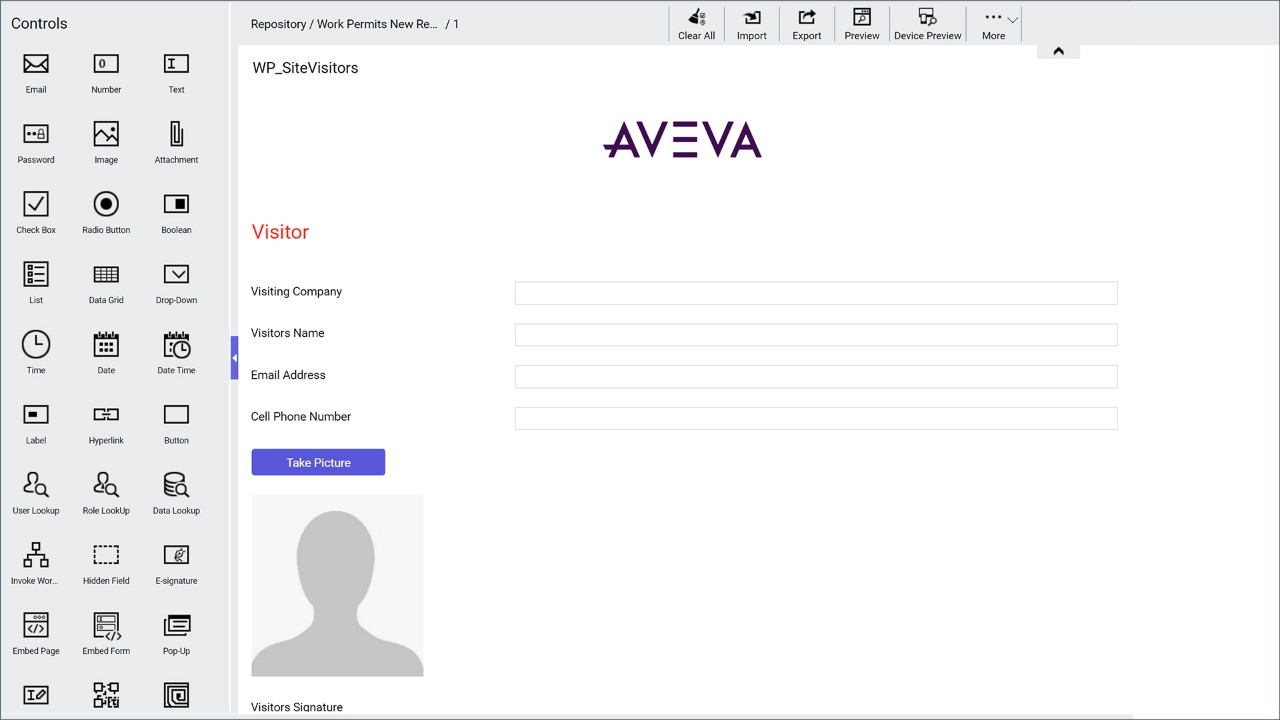

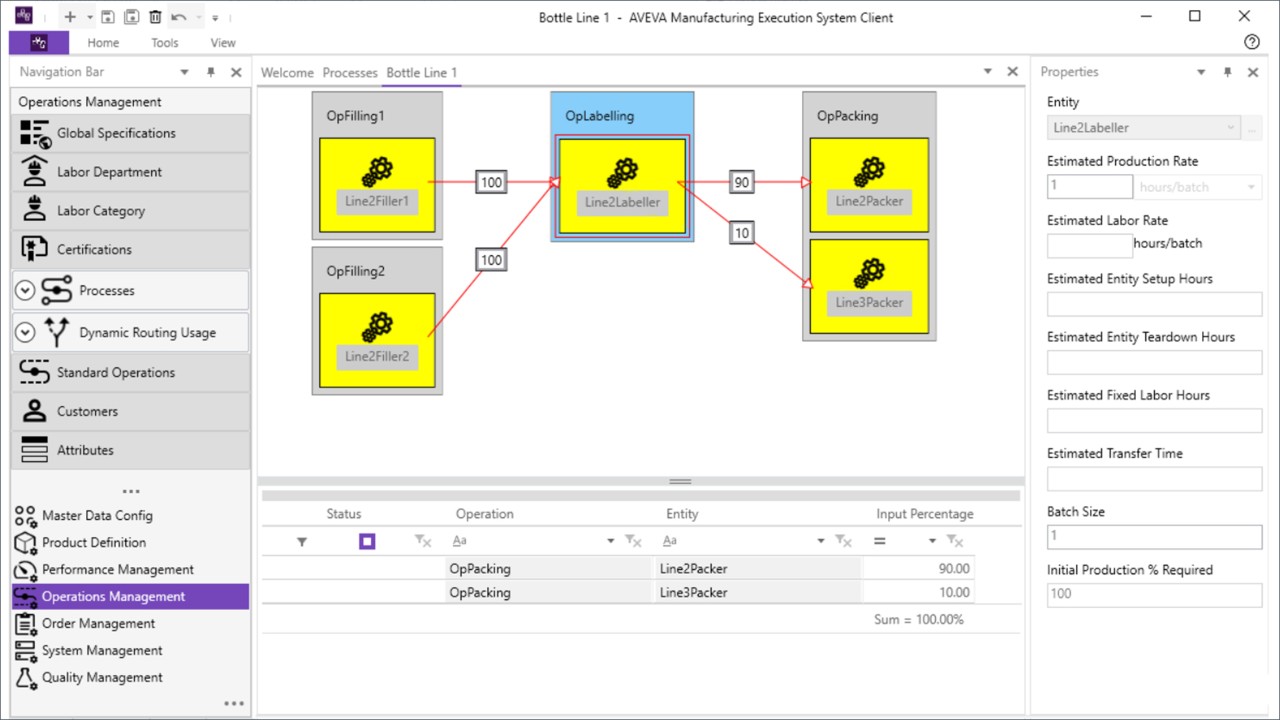

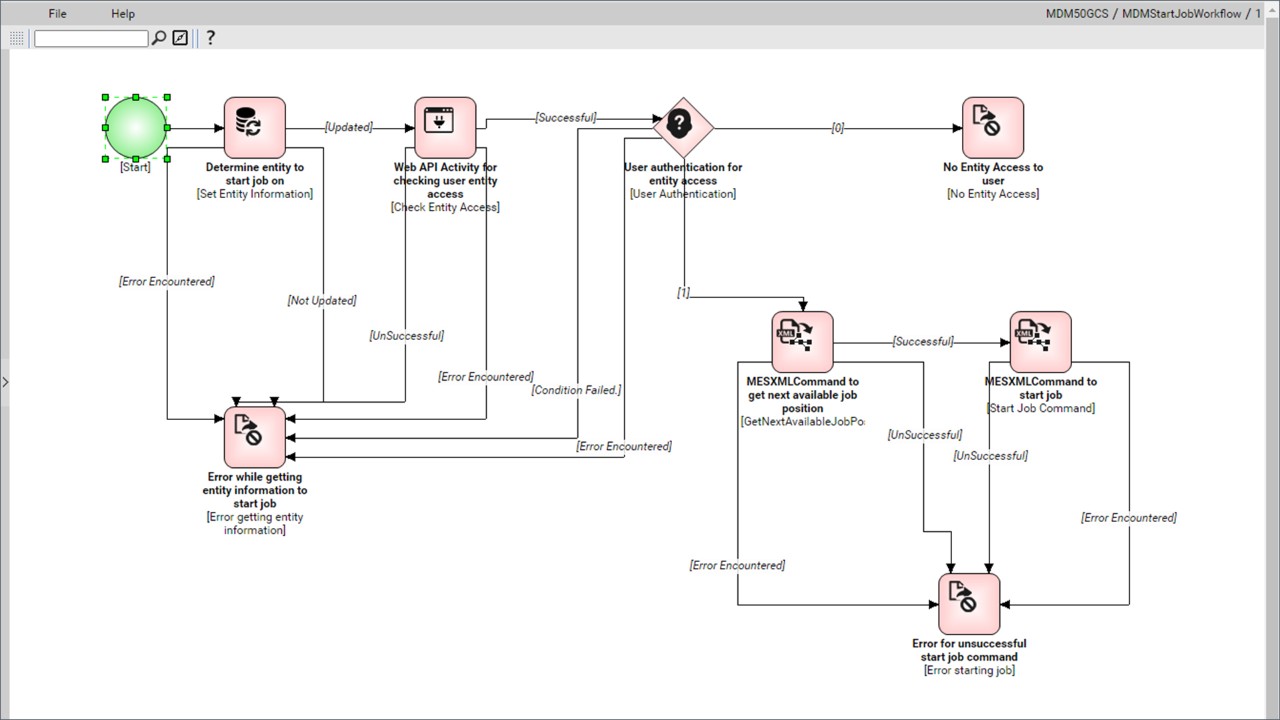

AVEVA™ Manufacturing Execution System (MES) offers comprehensive control over plant workflows, delivering real-time visibility into manufacturing processes to ensure high-quality products at minimal cost. It enables full traceability from raw materials to finished goods, helps mitigate safety risks, automates data collection, and leverages cloud-based analytics to optimize operational efficiency across your global production network.

Benefits of AVEVA™ Manufacturing Execution System

Efficiency

Enhance worker productivity and streamline processes by empowering teams with real-time visibility and control over production, inventory, and quality workflows.

Product Quality

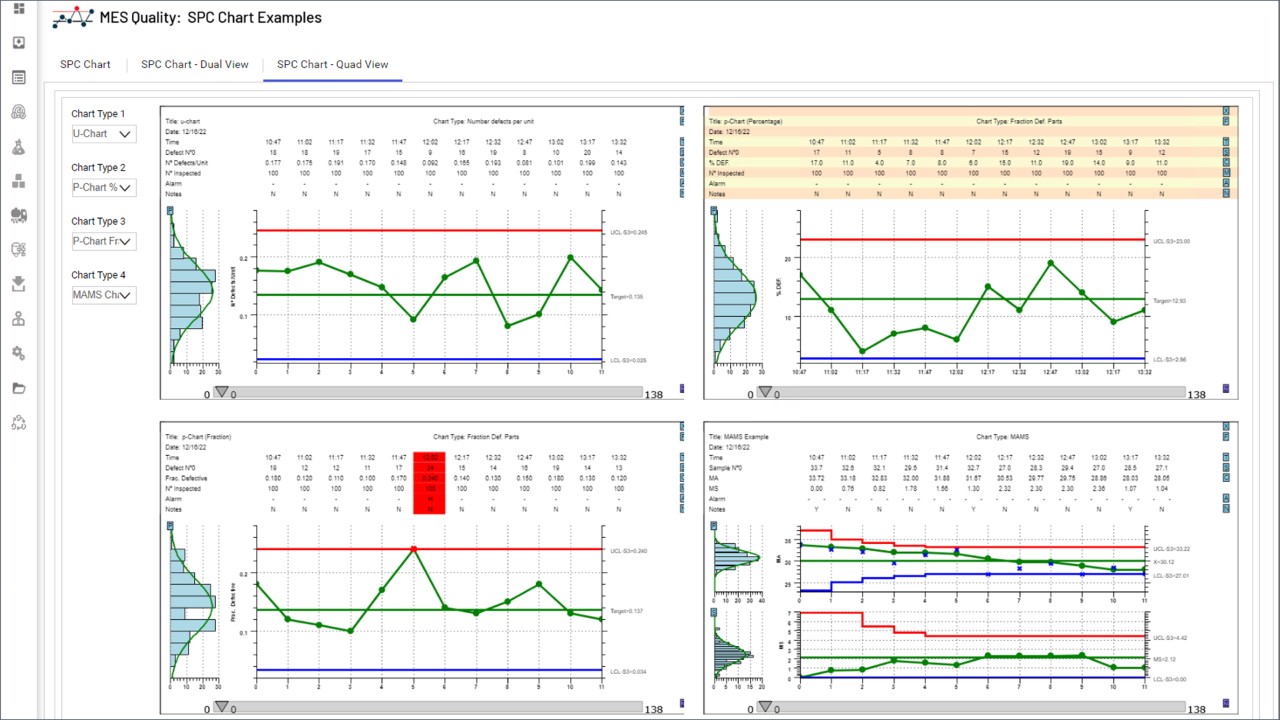

Improve product quality, ensure compliance, and boost customer satisfaction by automating quality control and enabling rapid traceability from finished goods back to raw materials.

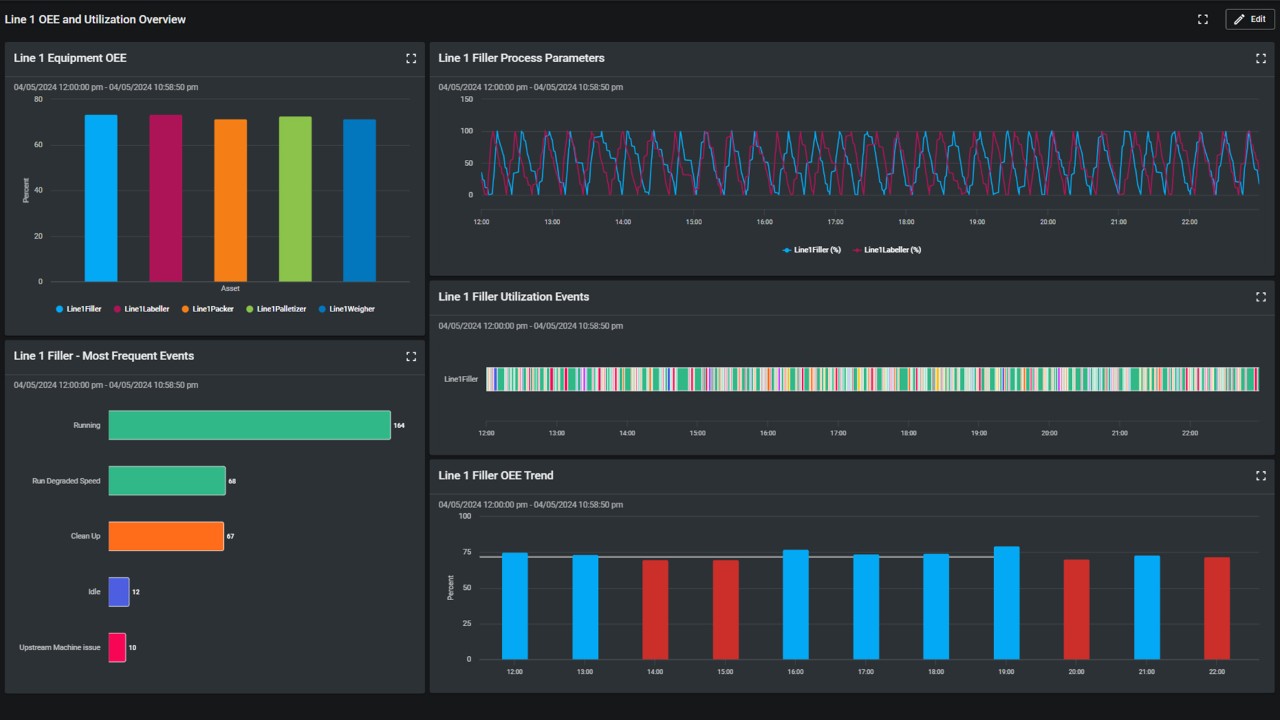

Visibility & Cloud

Achieve enterprise-wide transparency with a unified, 360-degree view of your operations—whether within a single plant or across multiple sites—leveraging cloud technology and AI to unlock the full potential of your data.

Features of AVEVA™ Manufacturing Execution System

How You Can Use AVEVA Manufacturing Execution System

RESOURCES