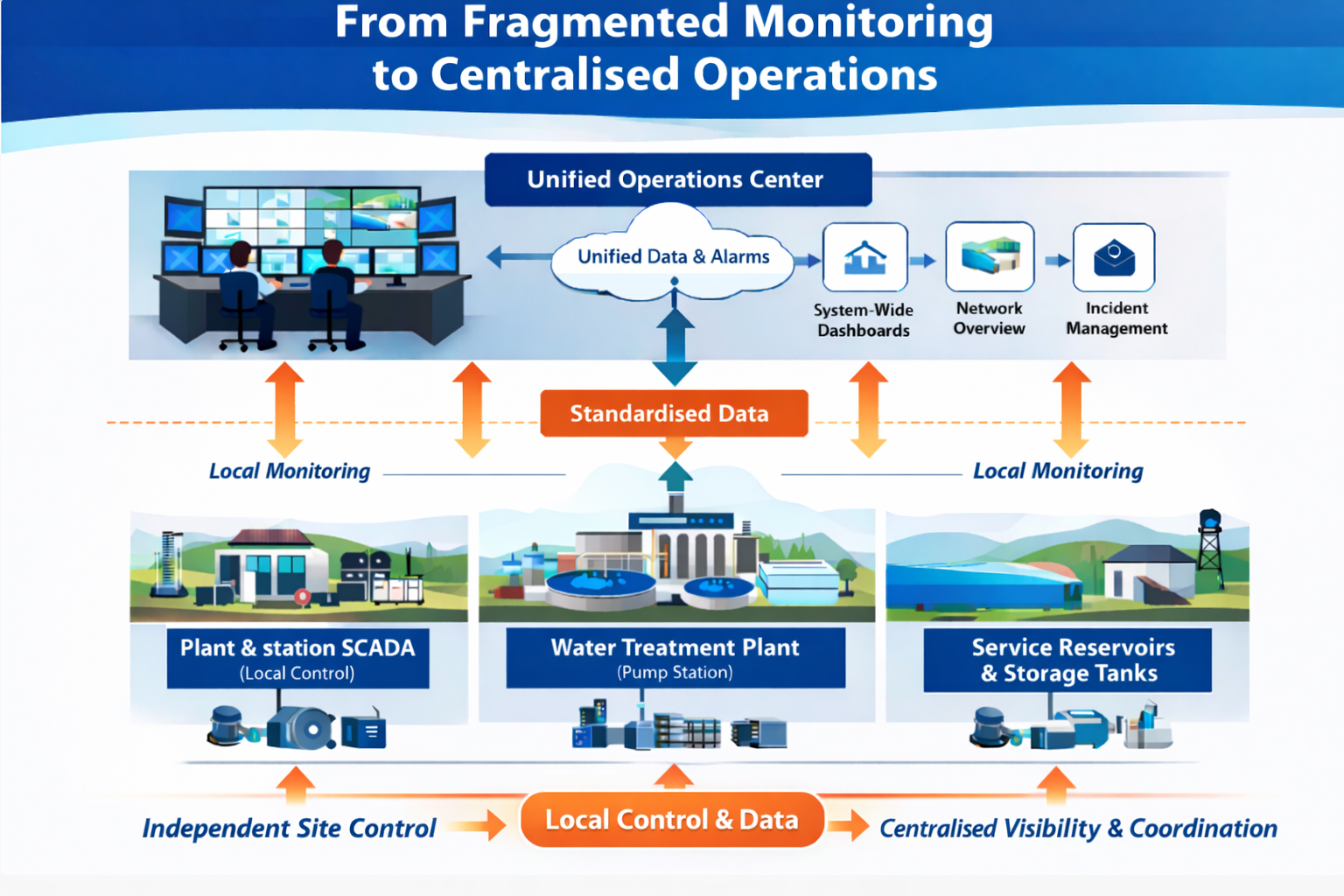

Issue 3 — From Fragmented Monitoring to Centralised Operations

Once pumping stations are stabilised and field data becomes reliable, many water utilities encounter a familiar situation:

They now have more data —

but still struggle to see the whole system clearly.

When Reliable Data Still Lives in Silos

After upgrading field infrastructure, utilities often find that:

- Pumping stations are operating more reliably

- Alarms are more consistent

- Operators have greater confidence in remote data

Yet operations remain fragmented.

Each plant, station, or zone still has its own operational view.

Operators continue to focus on local conditions.

Supervisors still piece together information from multiple screens and reports.

The question shifts from “Can we trust the data?”

to “How do we see everything together?”

Why Fragmentation Persists — Even with Good SCADA

Most water utilities already operate proven SCADA systems, such as AVEVA Plant SCADA, to run plants and pumping stations safely.

Plant SCADA excels at:

- Real-time monitoring and control

- Alarm handling and interlocks

- Day-to-day operator actions

- Keeping individual facilities running reliably

However, SCADA systems are typically designed around local operations.

As networks grow, this leads to:

- Multiple SCADA views across different sites

- Inconsistent layouts and naming conventions

- Limited visibility of system-wide impact

- Heavy reliance on experience to connect the dots

Nothing is “wrong” with SCADA —

it is simply doing what it was designed to do.

The Shift from Operating Sites to Managing the Network

At this stage, utilities begin to recognise a change in operational needs.

Instead of only asking:

Is this pump running correctly?

They start asking:

What is happening across the entire water network right now?

This marks a shift from site-level operation

to network-level coordination.

Centralised Operations Without Disrupting Control

Centralised operations do not mean replacing existing SCADA systems.

In practice, successful utilities:

- Retain Plant SCADA for local control and safety

- Standardise data models and structures

- Surface key operational information centrally

This is where a Unified Operations Center becomes relevant.

Built on platforms from AVEVA, a Unified Operations Center provides:

- A consolidated view across multiple plants and stations

- Consistent presentation of operational status

- System-wide awareness for supervisors and managers

- Faster confirmation of whether an issue is isolated or widespread

Importantly, control remains at the plant and station level.

Operators continue to run facilities through Plant SCADA.

The Unified Operations Center adds visibility and coordination, not risk.

What Changes Day to Day

When centralised operations are introduced thoughtfully, utilities begin to notice practical changes:

- Supervisors spend less time calling sites for confirmation

- Operators escalate issues with clearer context

- Management gains visibility without interfering with operations

- Incident response becomes calmer and more coordinated

The system does not become more complex.

It becomes more understandable.

Centralisation as an Operational Enabler

Centralised operations are often misunderstood as a management tool.

In reality, they support everyone:

- Operators feel supported, not monitored

- Supervisors make faster, more confident decisions

- Maintenance teams gain clearer operational context

- Management sees the system without disrupting it

This is not about control from above.

It is about clarity across the network.

Setting the Foundation for What Comes Next

By this stage, utilities typically have:

- Reliable field data

- Stable local operations

- A unified operational view

Only now does data begin to feel useful beyond the moment.

Questions start to change again:

- Can we learn from past events?

- Why do certain issues repeat?

- Can data support better maintenance decisions?

These questions lead naturally toward using historical data more effectively.

Coming Next: Issue 4 — When Data Starts to Work for Operations

In the next issue, we explore how utilities begin using operational history — often through Historian systems — to support condition-based decisions, root-cause analysis, and more informed maintenance planning.

Ready to Digitize, Unify, and Optimize?